In the world of custom packaging, the style and structure of your box matter just as much as the material. The way a box opens, folds, or displays your product can significantly influence customer experience, product safety, and brand perception. Whether you’re a small business packaging handmade goods or an established brand launching a new product line, understanding different packaging box styles will help you make smarter, more strategic decisions.

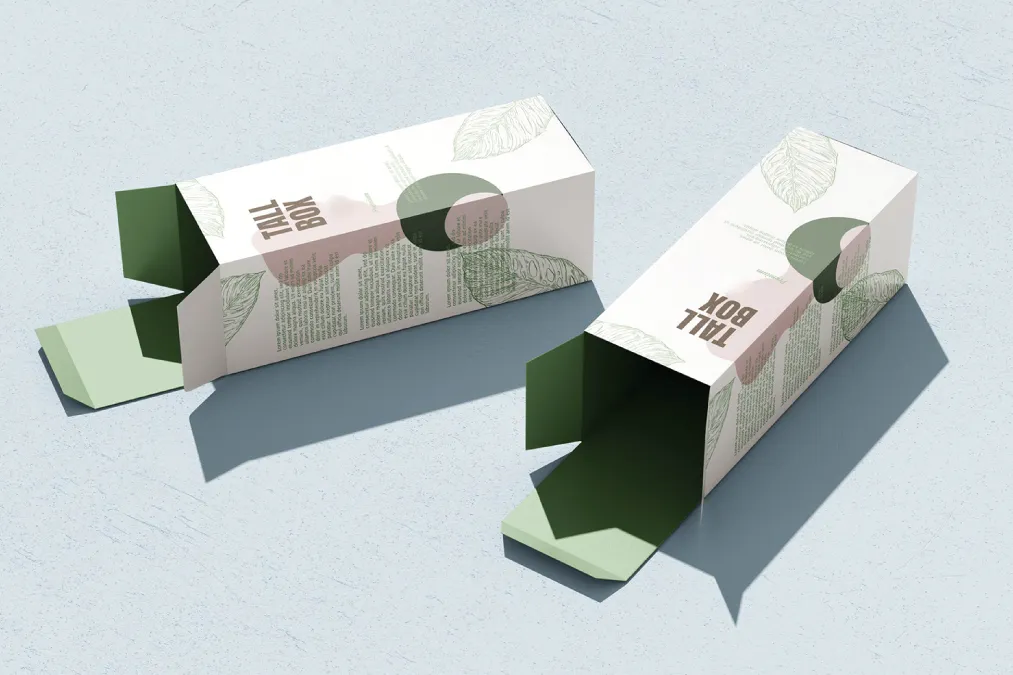

From classic tuck-end boxes to sleek drawer-style packaging, this guide breaks down the most popular packaging structures, the difference between flat and assembled formats, and how to choose the best box style for your product.

Why Box Structure Matters

The structure of a box is more than just its shape — it determines how your product is presented, how easy it is to store and ship, and how effectively it communicates your brand. For example, a luxury item in a rigid drawer box delivers a premium feel, while a functional mailer box offers practical, protective packaging for e-commerce orders.

Each box style is designed with a purpose — whether it’s protection, retail display, unboxing impact, or convenience. Choosing the wrong structure can lead to damaged products, excessive shipping costs, or a poor first impression.

Common Box Styles in Custom Packaging

Let’s explore some of the most commonly used custom packaging box styles and their ideal applications.

Tuck-End Boxes

Tuck-end boxes are among the most popular and versatile packaging styles. They’re often used for lightweight retail products like cosmetics, supplements, and electronics accessories. The design includes top and bottom flaps that tuck into the box, making them easy to assemble, open, and reseal.

There are several subtypes of tuck-end boxes:

- Straight tuck-end boxes have both flaps on the same side, creating a clean front panel, ideal for display.

- Reverse tuck-end boxes have flaps on opposite sides, which can sometimes save material or simplify production.

Tuck-end boxes are cost-effective, stackable, and suitable for automated or manual packaging lines.

Mailer Boxes

Mailer boxes are designed for strength and self-locking security. Made from corrugated board, they are ideal for shipping and unboxing experiences. Their hinged lid and dust flaps protect contents without needing additional tape or sealing.

This box style is widely used in e-commerce for products like clothing, skincare kits, tech accessories, and subscription boxes. Brands love mailer boxes because they can be printed inside and out, offering an immersive brand experience for the customer.

Mailer Packaging boxes arrive flat but are easy to assemble by hand. They offer a professional look while keeping your product safe in transit.

Sleeve Boxes

Sleeve packaging boxes consists of a tray or inner box that slides into an outer sleeve. This style gives a sleek, elegant presentation, often used for premium products, gift sets, or minimalist designs. It allows for unique branding — the outer sleeve can be printed or embossed, while the inner tray can be plain or custom-fit to the product.

Sleeves are a great way to keep packaging compact while still delivering a sophisticated feel. They also allow for quick unboxing without tearing or damage.

Drawer Boxes (Slide Boxes)

Drawer-style boxes take the sleeve concept a step further with a more rigid structure. The inner compartment, often called the drawer, slides out smoothly from the outer casing. These boxes are typically made from rigid paperboard and are common in the luxury sector — think jewelry, perfume, watches, or premium chocolate.

Drawer boxes elevate the unboxing experience and add an element of surprise and delight. They offer excellent branding opportunities and are also sturdy enough for reuse, which increases brand exposure.

Two-Piece Boxes (Lid and Base)

A two-piece box features a separate lid and base and is often used in packaging for clothing, electronics, or luxury items. The lid can be shallow or deep, depending on how you want the product to be revealed.

These boxes are strong, classic, and elegant. They’re particularly effective when you want the packaging to feel like a keepsake — something the customer may retain even after using the product.

Flat vs. Assembled Packaging: What’s the Difference?

When ordering custom packaging, you’ll often need to decide between flat-packed and fully assembled boxes. Each has its advantages depending on your business model and logistics.

Flat packaging means the boxes are delivered in a collapsed form and must be folded or assembled before use. This is ideal for saving space during shipping and storage, and it’s typically more cost-effective for large quantities. Flat-packed boxes are common with tuck-end, mailer, and cardboard cartons.

Assembled packaging is delivered pre-constructed and ready to use. This option saves time during fulfillment, especially for smaller runs or luxury products that require a sturdy, rigid form. Rigid drawer boxes or two-piece boxes are often supplied assembled due to their non-collapsible structure.

If you have high-volume shipping and in-house assembly capabilities, flat-packed boxes will likely suit you better. But if you need packaging that’s ready to go or you’re creating a luxury unboxing experience, pre-assembled boxes are worth the investment.

Enhancing Functionality with Custom Inserts

Inserts are a critical component of structured packaging, especially when your product needs to be secured during transit or displayed neatly inside the box. A custom insert can be made from cardboard, foam, molded pulp, or plastic, depending on the level of protection and presentation you want.

Inserts help:

- Prevent movement or breakage during shipping

- Organize multiple items in one package

- Enhance perceived value and unboxing experience

For example, a skincare gift set may use a die-cut cardboard insert to keep bottles upright and evenly spaced. A tech product might use foam to secure components, while food brands can use Kraft inserts to hold fries, sauces, or toppings in place.

By using custom inserts, you not only protect your product — you elevate your packaging and build trust with your customers.

Which Packaging Style Is Best for Your Product?

Choosing the right structure depends on several factors:

- Product type and fragility

- Customer experience goals

- Shipping and storage conditions

- Retail vs. e-commerce channel

- Brand identity and presentation

A delicate product like handmade candles might benefit from a drawer box with foam inserts, offering both protection and visual appeal. A fast-moving retail item, like a beauty serum, may be better suited to a tuck-end box with simple branding. For online orders, a custom mailer box offers durability and a ready-to-ship solution that also doubles as your brand’s first physical impression.

Final Thoughts: Structure That Supports Your Brand

Packaging isn’t just a box. It’s an experience, a protector, and a storyteller. The structure you choose can elevate your brand, improve product safety, and create lasting customer impressions. Whether you’re aiming for function, luxury, or sustainability, there’s a packaging style that fits your vision.

At Bee Printers, we specialize in creating custom packaging tailored to your brand’s needs — from tuck-end cartons and sleeve boxes to luxury drawer packaging and durable mailers. Our experts can guide you through selecting the perfect box structure, adding inserts, and optimizing your packaging for performance and presentation.