Measuring your box correctly is one of the most significant, though seemingly forgotten, part of ordering custom packaging boxes. Be it retailing, e-commerce, food delivery services or products manufactured, the knowledge of determining proper measurement of boxes will make your products fit snug, appear professional and save your money terrified as far as shipping or storage expenses are concerned.

Why Measuring Correctly Matters

Correct box measurements ensure:

- A snug and safe fit for your product

- Reduced material waste and cost

- Enhanced unboxing experience for customers

- Accurate quotes from packaging suppliers

Wrong dimensions may result in huge packages that may break the product on the way or even attract a return fee, which will finally hit your pocket.

Internal vs. External Dimensions: What’s the Difference?

It is essential to learn the distinction between internal and external measurements of the boxes so that an order of custom packaging can be placed.

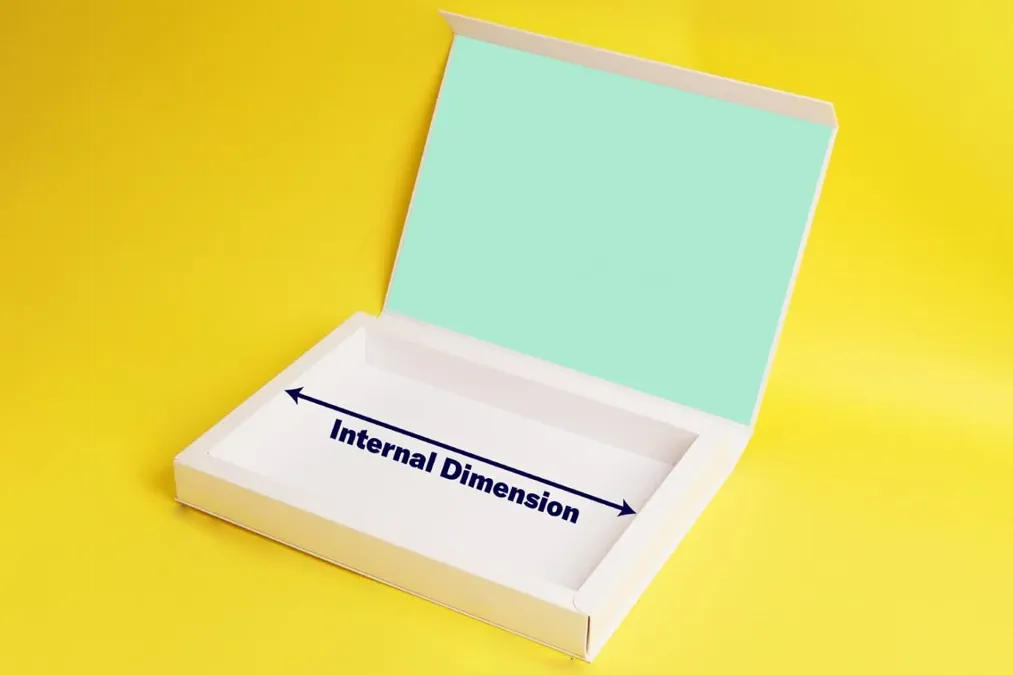

Internal Dimensions

The inside dimensions are the inside space of the box these are the literally usable space you will put your product into. These are the measurements most requested by the packaging companies in making the custom packaging boxes or inserts.

Use internal dimensions when:

- You’re designing packaging for a specific product fit

- The box needs to hold multiple items, padding, or trays

- You want exact control over internal space

External Dimensions

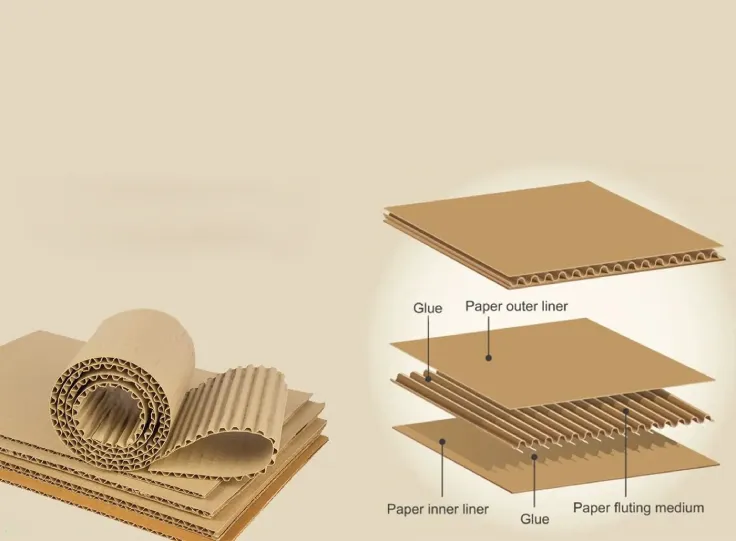

The external dimensions are measured on the exterior of the box and the material thickness (flute or board type). This is significant to shipping and storing reasons these are specifically vital when made in the interest of minimization of palletizes or shelf space.

Use external dimensions when:

- You’re calculating shipping costs

- Stacking or storing boxes

- Packaging has to fit into another container

Pro Tip: Always clarify with your packaging supplier whether they require internal or external dimensions.

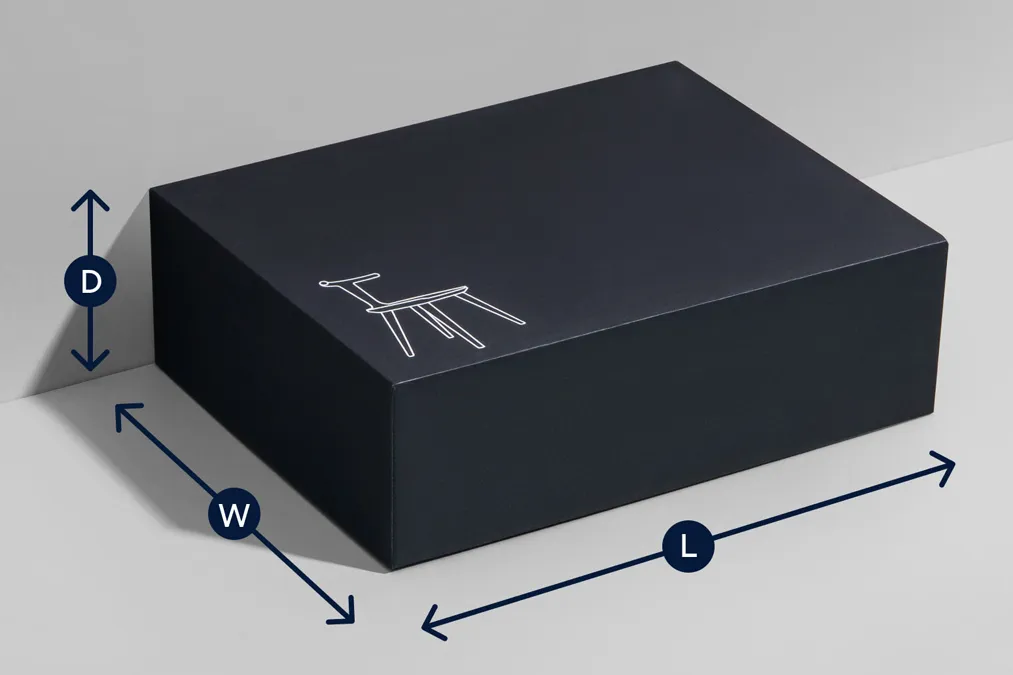

How to Measure a Box: Length × Width × Depth

Box measurements are always listed in the same sequence:

Length × Width × Depth (Height)

Understanding these three dimensions helps prevent miscommunication with your packaging supplier.

1. Length (L)#

The longest side of the box that lies along the opening. This is measured from left to right.

2. Width (W)

The shorter side that also lies along the opening, measured from front to back.

3. Depth (D)

Also called height, this is measured from top to bottom, or from the opening to the base of the box.

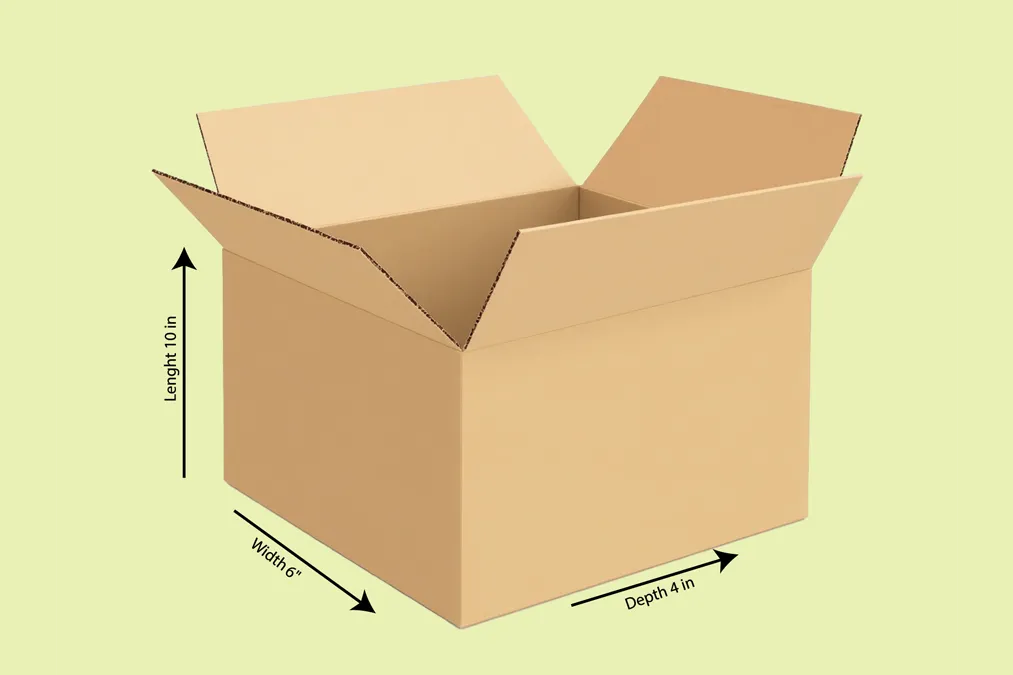

Example:

If a box measures 10″ × 6″ × 4″, then:

- 10″ is the length

- 6″ is the width

- 4″ is the depth (height)

Tips for Accurate Box Measurement

Measurement Before you order custom packaging boxes, remember that they have to be exactly the right size for your product and only with these practical tips, you can be sure your product will fit in your boxes.

Use a Rigid Ruler or Measuring Tape

Use tools that provide clear and precise readings in inches or millimeters.

Measure the Product First

Always start by measuring your product (including accessories or padding), then add space if needed for protection.

Round Up, Not Down

If your product is between two sizes, round up slightly to allow for packing materials or ease of fit.

Account for Packaging Layers

If your product includes trays, foam inserts, or inner wraps, make sure these are factored into your measurement.

Take Multiple Measurements

Measure twice (or three times!) to avoid any miscalculations.

Common Mistakes to Avoid

Even experienced buyers sometimes make mistakes when ordering custom packaging boxes. Here are some common errors you can steer clear of:

1. Confusing Width and Depth

This happens often and can result in boxes that open incorrectly or don’t hold the product properly.

2. Not Confirming Measurement Units

Mixing inches with centimeters or failing to confirm the unit type can lead to major sizing issues.

3. Forgetting to Include Extra Space

Products that are too snug in a box may get damaged. Always allow room for protective padding like bubble wrap or paper.

4. Using External Instead of Internal Dimensions

This can result in boxes being too small for your product. Always use internal dimensions when sending specifications to packaging companies.

When Should You Order Custom Packaging Boxes?

Measuring your box is just the first step. You should consider custom packaging when:

- Launching a new product line

- Wanting to create a premium unboxing experience

- Shipping fragile or uniquely shaped items

- Looking to build your brand with custom printed packaging

Custom-sized boxes reduce waste, protect your goods, and create a more professional look — essential for businesses wanting to stand out.

Final Thoughts: Partner with a Reliable Custom Packaging Expert

No matter what you ship burgers, gadgets, clothes, cosmetics, etc. A perfectly deployed sized box can help store, present and transport products, and help cut down on the cost. The key ingredient of quality packaging is getting your measures right.

At BeePrinters, we specialize in producing custom burger boxes, fries packaging, and a wide range of custom food-grade packaging — all made to your exact dimensions. Our team can guide you through every step, from sizing and design to delivery.

FAQs

1. How to measure a box for packing?

Measure the internal dimensions in this order: Length × Width × Depth. Use a ruler or tape for accurate results.

2. How to calculate box packing?

The depth, length and width of a box should be multiplied to give volume useful in determining the amount of space or material to be used.

3. How do you calculate the size of a box?

Measure all three sides (length, width, depth) from the inside edges to determine the usable space for your product.

4. How to determine packing size?

Packing size is based on the external dimensions, considering product size plus padding or fillers to protect items during transit.

5. What are the measurements for making a box?

Use the internal size (Length × Width × Depth) to design the box, and add thickness for the external structure if needed.